Product Line-Ups

-

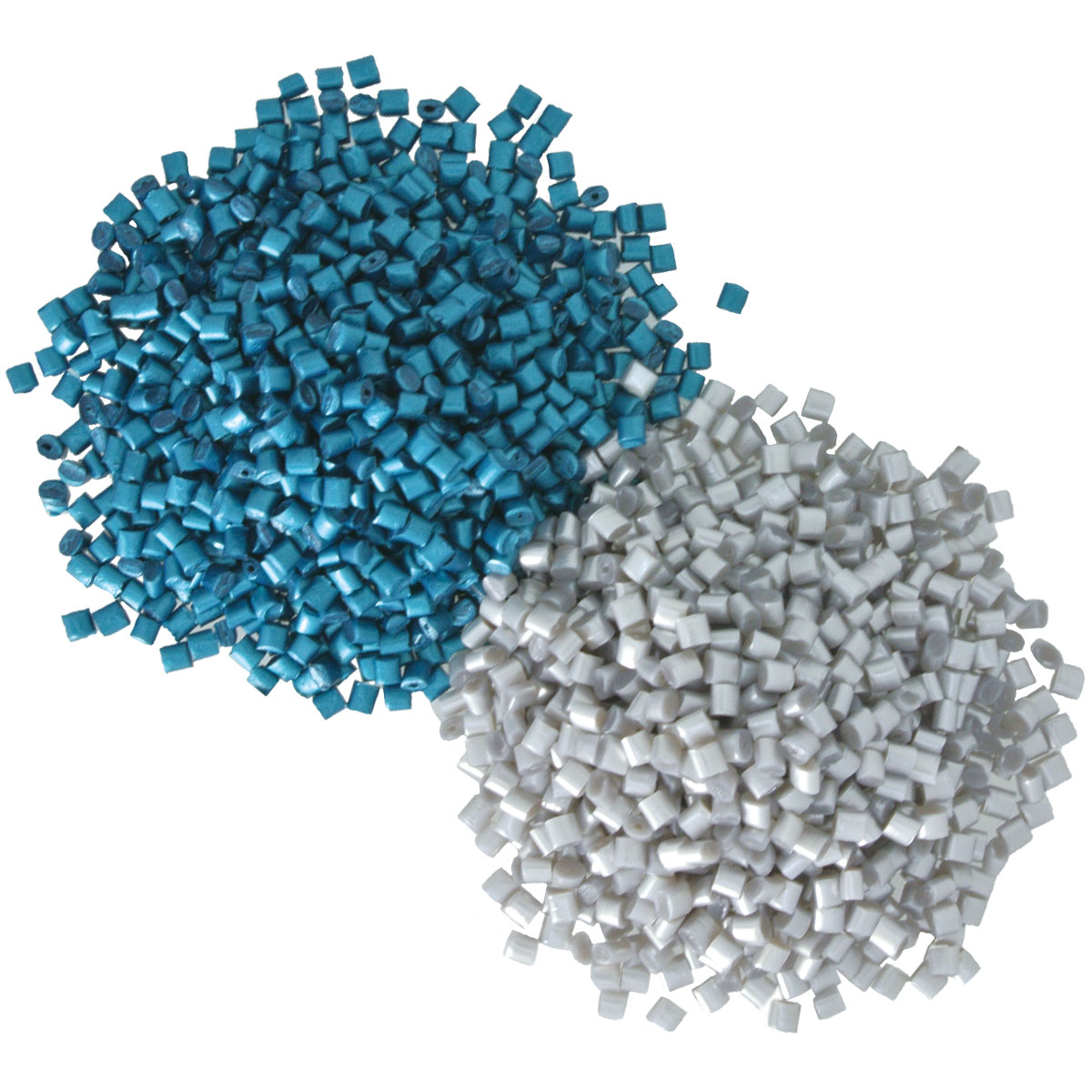

Masterbatch

An economical yet highly concentrated mixture of pigment and/or additives developed for outstanding dispersion using our own technology and manufacturing methods.

Our unique production technology will fulfill your requirements quickly whatever the production lot is. Consistent quality is ensured using our own Spectro-photometer testing equipment.

-

Dry Color

Low Cost coloring pigment in dry powder form with good dispersion.

Pigments and dyestuff in powder form provides the quickest and the most economical way to fulfill your coloring requirements in small production runs.

-

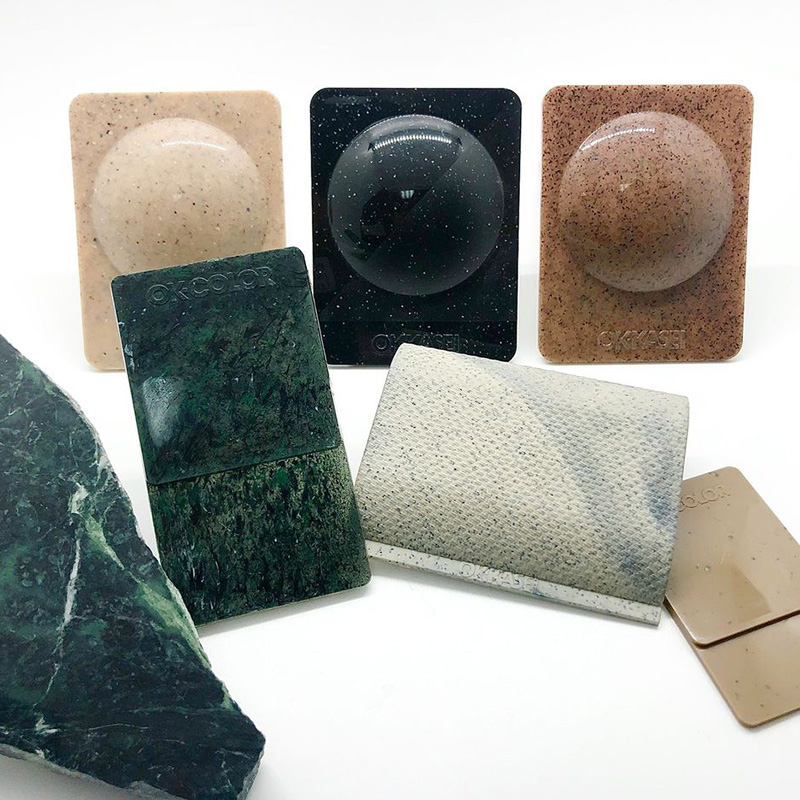

High Performance Value-added Masterbatch

Masterbatch with benefit for design and functionality such as marble, metallic, pearl, aluminum and glass flake effects.

High-Performance colorants to enhance the appearance are available with functional materials such as anti-static agent, weathering agent and scratch resistant agent.

Have some colors in mind?

Try our color matching request form!

Specialty Effects

Below are the Commodities we produce

-

Marble Specialty Effects in Styrenic resin

Marble Specialty effects masterbatch uniquely developed and formulated exclusively for styrenic resin.Recommended Resins: PS/SAN/ABS/PMMA/PBT

Molding conditions:

Molding temperature range: 430℉~480℉

Slightly higher molding temperature than normal and low backpressure is recommended. The marble pattern and size is dependent on the base resin’s melt index(MI) and molding condition. When the resin’s MI is high, the marble effect will become more condensed. When the resin’s MI is low, the marble effect will become more elongated. Since the marble effect is dependent on several factors such as molding conditions, mold design, and type of gate used etc., Please make adjustments to achieve the best result.

-

Marble Specialty Effects in Olefin resin

Marble specialty effects masterbatch create 3D like patterns when combined with base material using normal injection molding process.Recommended Resins: PP/PE

Molding conditions:

Molding temperature Range: 360℉~510℉

Normal molding conditions can be used without special equipment or mold modifications. The marble pattern and size will be dependent on several factors such as molding condition, mold design and the type of gate used etc., Please make adjustments to achieve the best result.

-

Metallic Specialty Effects

Specialized color to create a real metallic effect in molded plastic products can achieve a lustrous metallic finish without painting.Features:

Metallic Specialty Effect are used in a wide range of applications from appliances to automotive parts. Our specialized proprietary formulations were developed to economically reduce metallic effects normally achieved by a secondary process of painting.

-

Super High Gloss Metallic Effects

Super High Gloss color masterbatch with enhanced brilliance in metallic effect.Features:

Super High Gloss Metallic Effects intensifies the overall brilliance of the metallic.

This specialty metallic will even maintain its brilliance when added to muted colors which normally become hazy when paired together. You can easily mold high quality products benefiting from easy processability and good dispersion. Thus achieving much higher glow when compared to aluminum.

-

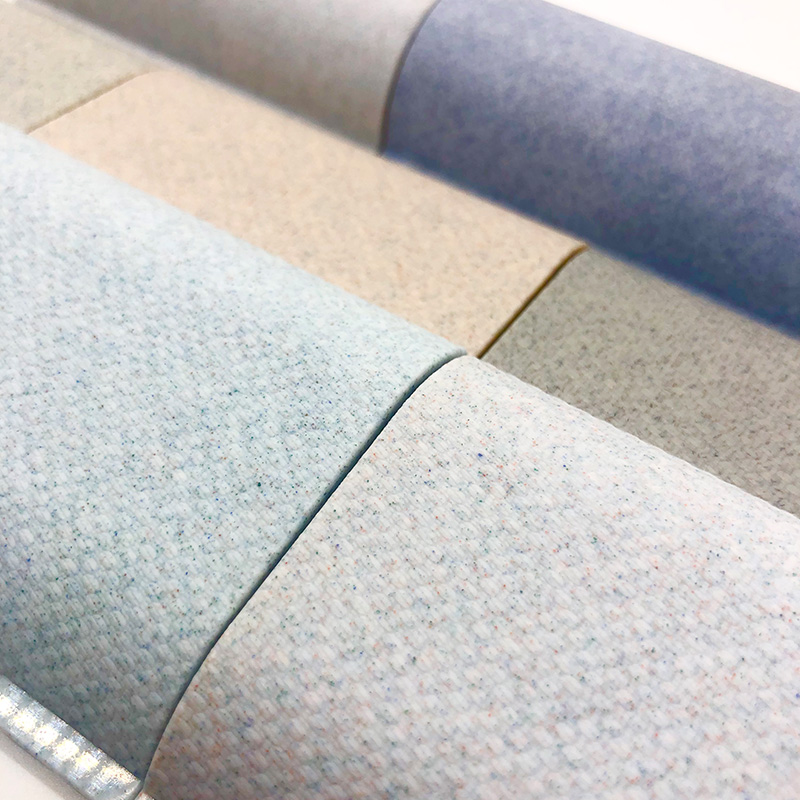

Fabric Specialty Effects

Our Fabric Colors can emulate the softness of fabrics using textile fiber material.Features:

Fabric colors will replicate the appearance and color tone of fabric with the sense of warmth and comfort. It is developed from a combination of plastic and fiber materials in various sizes and colors. You can easily create the texture of fabrics and cross tones regardless of the base resin type. You can also create numerous combinations of patterns and base colors.

-

Stone Specialty Effects/ Glass Specialty Effects

Stone Specialty Effects creates the natural appearance of stone and Glass Specialty Effects create transparent stained glass appearance.Features:

Stone Specialty Effects

Stone color creates the natural appearance of real stone by adding modified particles to base colors applicable to a wide range of resins.Glass Specialty Effects

By addind Mica or other functional materials, it can create a transparent stained glass look. Futhermore, frost glass appearance can be achieved by using different functional mateials.